TA2 titaniyamu aloyi chubu ntchito mafakitale

TA2 Titanium Alloy Pipe, Ubwino

TA2 Titanium Alloy Pipe, Poyerekeza ndi zitsulo zina, ili ndi izi:

1. Mphamvu zenizeni zenizeni (mphamvu / kachulukidwe) (onani chithunzi), mphamvu yowonongeka imatha kufika 100 ~ 140kgf / mm2, pamene mphamvuyi ndi 60% yokha yazitsulo.

2. Sing'anga kutentha mphamvu zabwino, ntchito kutentha ndi madigiri mazana angapo apamwamba kuposa aloyi aloyi, mu sing'anga kutentha akhoza kukhalabe mphamvu zofunika, akhoza kugwira ntchito mu 450 ~ 500 ℃ kutentha kwa nthawi yaitali.

3. Good dzimbiri kukana, titaniyamu pamwamba mu mlengalenga yomweyo anapanga wosanjikiza yunifolomu ndi wandiweyani okusayidi filimu, amatha kukana zosiyanasiyana kukokoloka TV.Titaniyamu nthawi zambiri imakhala ndi kukana kwa dzimbiri muzakudya za okosijeni komanso zosalowerera ndale, makamaka m'madzi a m'nyanja, m'madzi a m'nyanja, m'madzi a chlorine ndi ma chloride.Koma mu kuchepetsa sing'anga, monga hydrochloric acid solution, titaniyamu dzimbiri kukana ndi osauka.

4. Titaniyamu aloyi ndi ntchito yabwino otsika kutentha ndi otsika kwambiri chilolezo zinthu, monga TA7, akhoza kusunga pulasitiki ena pa -253 ℃.

5. Low zotanuka modulus, yaing'ono matenthedwe madutsidwe, palibe ferromagnetism.

6. Kuuma kwakukulu.

7. Katundu wosapondaponda bwino komanso thermoplasticity yabwino.

Chithandizo cha kutentha Titaniyamu aloyi amatha kupeza magawo osiyanasiyana komanso ma microstructure posintha njira yochizira kutentha.Nthawi zambiri amaganiziridwa kuti fine equiaxed microstructure ili ndi pulasitiki yabwino, kukhazikika kwamafuta komanso mphamvu ya kutopa.Mapangidwe a acicular ali ndi mphamvu zolimba kwambiri, mphamvu zokwawa komanso kulimba kwa fracture.Mapangidwe osakanikirana ndi acicular ali ndi mawonekedwe abwinoko.

TA2 Titanium Alloy Pipe, Njira zochizira kutentha zomwe zimagwiritsidwa ntchito nthawi zambiri ndi annealing, solution ndi ukalamba.Annealing ndikuchotsa kupsinjika kwamkati, kukonza pulasitiki ndi kukhazikika kwa microstructure, kuti mupeze zinthu zomveka bwino.Nthawi zambiri, kutentha kwa annealing kwa α alloy ndi (α + β) aloyi ndi 120 ~ 200℃ pansi pa kusintha kwa (α + β) -- → β gawo.Njira yothetsera ukalamba ndi kupeza α 'gawo ndi metastable β gawo la martensite mwa kuzizira mofulumira m'dera la kutentha kwambiri, ndiyeno kuwola magawo osakanikiranawa pogwira m'chigawo chapakati cha kutentha, ndikupeza magawo achiwiri obalalika. , monga gawo la α kapena gulu, kuti akwaniritse cholinga cholimbikitsa alloy.Nthawi zambiri (alpha + beta) aloyi kuzimitsa mu alpha + beta) -- - > beta gawo kusintha malo pansi 40 ~ 100 ℃, metastable beta aloyi kuzimitsidwa mu alpha + beta) -- - > beta gawo kusintha malo pamwamba 40 ~ 80 ℃.Kutentha kwa ukalamba nthawi zambiri kumakhala 450 ~ 550 ℃.Kuonjezera apo, pofuna kukwaniritsa zofunikira zapadera za workpiece, makampaniwa amagwiritsanso ntchito annealing kawiri, isothermal annealing, β kutentha kutentha, kutentha kwa deformation ndi njira zina zopangira zitsulo.

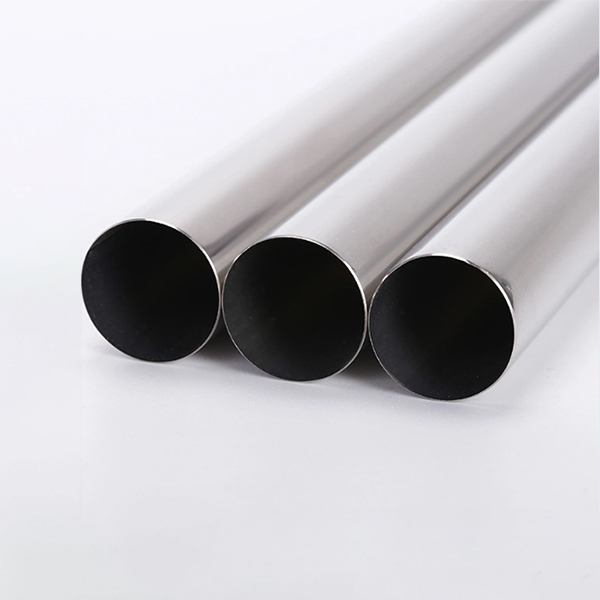

TA2 Titanium Alloy Pipe, Gulu

Chitoliro cha titaniyamu, chitoliro chowotcherera cha titaniyamu, titaniyamu splicing tee, titaniyamu splicing chigongono, titaniyamu kuwotcherera mphete, titaniyamu kuchepetsa, titaniyamu tee, titaniyamu chigongono, titaniyamu chimney, etc.

TA2 Titanium Alloy Pipe, Mfundo Yogwira Ntchito Ya

TA2 titaniyamu aloyi chitoliro, makamaka kulumikiza mitundu yonse ya titaniyamu payipi zida, ntchito kufalitsidwa zinthu pakati pa mitundu yonse ya zida, payipi ali kukana dzimbiri wa zinthu titaniyamu palokha, kuti m'malo payipi ambiri payipi wamba sangathe kukwaniritsa kufunika. .Nthawi zambiri ф 108 pamwambapa ndi mapaipi owotcherera.

Main Technical Parameters

| DN (mm) | Kuyeza m'mimba mwake (mm) | Zida |

| 15 | 18 | Mtengo wa TA2 |

| 20 | 25 | Mtengo wa TA2 |

| 25 | 32 | Mtengo wa TA2 |

| 32 | 38 | Mtengo wa TA2 |

| 40 | 45 | Mtengo wa TA2 |

| 50 | 57 | Mtengo wa TA2 |

| 65 | 76 | Mtengo wa TA2 |

| 80 | 89 | Mtengo wa TA2 |

| 100 | 108 | Mtengo wa TA2 |

| 125 | 133 | Mtengo wa TA2 |

| 150 | 159 | Mtengo wa TA2 |

| 200 | 219 | Mtengo wa TA2 |

| 250 | 273 | Mtengo wa TA2 |

| 300 | 325 | Mtengo wa TA2 |

| 350 | 377 | Mtengo wa TA2 |

| 400 | 426 | Mtengo wa TA2 |

| 450 | 480 | Mtengo wa TA2 |

| 500 | 530 | Mtengo wa TA2 |

| 600 | 630 | Mtengo wa TA2 |

Zowonetsera Zamalonda