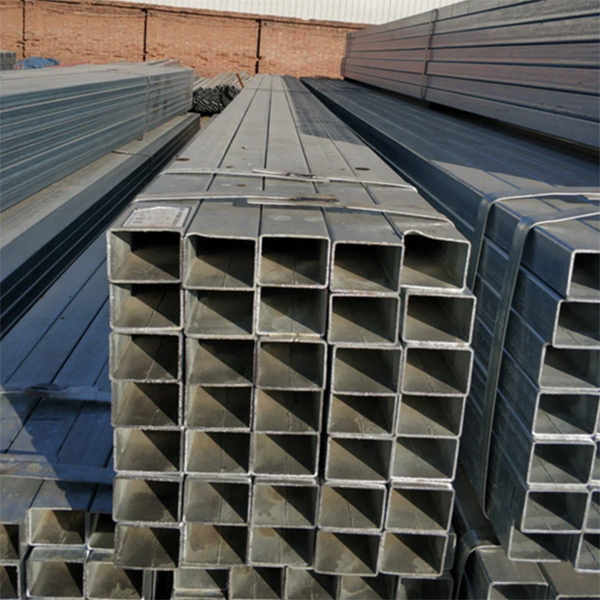

Square Structural Steel Tubing

Square structural steel chubing, yomwe imadziwikanso kuti welded chitoliro, imapangidwa ndi mbale yachitsulo kapena mzere pambuyo pakupanga kupanga welded square pipe.

Square structural zitsulo machubu, Zida zomwe zimagwiritsidwa ntchito ndi: Q235A, Q235C, Q235B, 16Mn, 20 #, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 01Ni10Cr18Cr19, 19Ni10Cr1, 1Ni13Cr1, 19Ni13Cr1, 19Ni13Cr19

Welded zosapanga dzimbiri chitoliro chokongoletsera (GB/T 18705-2002), welded zosapanga dzimbiri chitoliro chokongoletsera nyumba (JG/T 3030-1995), welded zitsulo chitoliro kwa otsika-anzanu madzimadzi mayendedwe (GB/T 3091-2001), ndi welded zitsulo chitoliro kwa exchanger kutentha (YB4103-2000).

Njira Yopanga

Square structural zitsulo chubu, Narrow akusowekapo angagwiritsidwe ntchito kupanga mipope welded ndi diameters lalikulu, ndi akusowekapo m'lifupi chomwecho angagwiritsidwe ntchito kupanga mipope welded ndi diameters osiyana.Koma poyerekeza ndi kutalika komweko kwa chitoliro chowongoka chowongoka, kutalika kwa weld kumawonjezeka ndi 30-100%, ndipo liwiro lopanga ndilotsika.

Chachikulu kapena wandiweyani m'mimba mwake lalikulu structural zitsulo machubu, Nthawi zambiri zopangidwa ndi zitsulo billet mwachindunji, ndi yaing'ono welded chitoliro woonda khoma welded chitoliro yekha ayenera mwachindunji welded kudzera zitsulo lamba.Pambuyo popukuta kosavuta, waya ndi wokonzeka.Choncho, yaing'ono m'mimba mwake welded chitoliro makamaka ntchito molunjika msoko kuwotcherera, lalikulu m'mimba mwake welded chitoliro makamaka ntchito kuwotcherera ozungulira.

Shape The Performance

square structural steel chubing, Ndi dzina la chitoliro cha square, chomwe ndi chitoliro chokhala ndi utali wofanana mbali zonse.Amapangidwa ndi chitsulo chotsitsa kudzera mu njira yothetsera ndikugudubuza.Nthawi zambiri, Mzerewu umasamutsidwa, wosalala, wopindika, wowotcherera mu chubu chozungulira, kenako ndikugudubuza chubu chozungulira Q215 chowotcherera chapakati ndikudula kutalika kwa kufunikira.Nambala yokhazikika ndi 50 pa paketi.Mphamvu imatanthawuza ntchito yokana kuwonongeka (kupindika koyenera kwa pulasitiki kapena kuthyoka) kwa data ya Q215 welded square pipe pansi pa katundu wosasunthika.Chifukwa katundu wa mawonekedwe amakokedwa, contraction, mapiringidzo, kukameta ubweya ndi njira zina, chifukwa mphamvu amagawidwa kumakokedwe mphamvu, compressive mphamvu, kupinda mphamvu, kukameta ubweya mphamvu ndi zina zotero.Mphamvu zamitundu yonse nthawi zambiri zimakhala ndi kulumikizana kotsimikizika, kugwiritsa ntchito mphamvu zolimba ngati singano yofunikira kwambiri.Mphamvu yokana chiwonongeko imatchedwa kulimba mtima.

Katundu pazigawo zomwe zikupita patsogolo kwambiri zimatchedwa charge array load.Mphamvu, pulasitiki ndi ngodya zomwe zimakambidwa kuseri kwa chitoliro cha chitoliro cha square chiyimire cholimba pansi pa zitsulo zopangira zitsulo zonse ndi makina ogwiritsira ntchito makina opangidwa ndi static katundu wa Q215 welded square pipe.M'malo mwake, makina ambiri akugwira ntchito mobwerezabwereza, pansi pa chilengedwe ichi mwayi wonse wotopa.Kutopa Mlingo ndiko kuyeza data yachitsulo yofewa komanso yolimba ya singano.Njira yosowa kwambiri ya mkati Angle kukonza m'moyo wapano ndi kukakamiza Angle njira, yomwe ndikugwiritsa ntchito nambala inayake ya momwe mutu wapanikizi ulili pansi pa katundu wina umakanikizidwa muyeso yoyesedwa Q215 welded square chubu data surface, malinga mpaka kukakamizidwa kulowa mulingo kuti mudziwe mtengo wa Angle.Njira zochepa zomwe zimagwiritsidwa ntchito ndi HB, HRA, HRB, HRC ndi HV.Angular plasticity imatanthawuza mphamvu ya deta yachitsulo pansi pa katundu, pulasitiki deformation (mapindikidwe okhazikika) popanda kuwonongeka.Pulasitiki Q215 welded square chubu sanali wamba machubu opanda msokonezo ndi mozungulira mozungulira chubu extrusion akamaumba.Chubu chopanda msoko ndi mfundo zowotcherera zimatanthawuza, ndi mtundu wachubu wa sikweya (torque chubu), mzimu wamitundu yambiri yazinthu zimatha kupanga chitoliro chaphwando (square torque chubu), ndi sing'anga kuchokera, bwanji, ntchito yanji ndi chapakati, lalikulu ochepa Q215 welded lalikulu chubu zitsulo chubu monga ochepa, kwa lalikulu chubu dongosolo, njereza lalikulu chubu, omanga chitoliro (square makokedwe chubu), etc. Square chubu Chiyambi Square chubu ntchito.

Chemical Composition

Zithunzi za S460N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kukula 0.2 | pa 0.6 | 1 - 1.7 | pa 0.8 | kukula 0.03 | kukula 0.025 | kupitirira 0.3 | kukula 0.1 | kukula 0.2 | kukula 0.025 | kukula 0.05 | kukula 0.05 | kukula 0.02 | kukula 0.55 | kukula 0.55 |

Zithunzi za S420N

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kukula 0.2 | pa 0.6 | 1 - 1.7 | pa 0.8 | kukula 0.03 | kukula 0.025 | kupitirira 0.3 | kukula 0.1 | kukula 0.2 | kukula 0.025 | kukula 0.05 | kukula 0.05 | kukula 0.02 | kukula 0.55 | kukula 0.52 |

Zithunzi za S420NL

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kukula 0.2 | pa 0.6 | 1 - 1.7 | pa 0.8 | kukula 0.025 | kukula 0.02 | kupitirira 0.3 | kukula 0.1 | kukula 0.2 | kukula 0.025 | kukula 0.05 | kukula 0.05 | kukula 0.02 | kukula 0.55 | kukula 0.52 |

Zithunzi za S460NL

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kukula 0.2 | pa 0.6 | 1 - 1.7 | pa 0.8 | kukula 0.025 | kukula 0.02 | kupitirira 0.3 | kukula 0.1 | kukula 0.2 | kukula 0.025 | kukula 0.05 | kukula 0.05 | kukula 0.02 | kukula 0.55 | kukula 0.55 |

Mechanical Properties

Zithunzi za S460N

| Kunenepa mwadzina (mm): | ku 100 | 100-200 |

| Rm- Mphamvu yamanjenje (MPa) | 540-720 | 530-710 |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 |

| ReH- Mphamvu zochepa zokolola (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Mphamvu yamphamvu (J) kutalika., (+N) | + 20 ° 55 | 0° pa 47 | -10 ° 43 | -20 ° 40 | |

| KV- Mphamvu yamphamvu (J) yodutsa, (+N) | + 20 ° 31 | 0° pa 27 | -10 ° 24 | -20 ° 20 | |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-200 |

| A- Min.elongation Lo = 5,65 √ Ndiye (%) | 17 | 17 | 17 | 17 | 17 |

Zithunzi za S420N

| Kunenepa mwadzina (mm): | ku 100 | 100-200 | 200-250 |

| Rm- Mphamvu yamanjenje (MPa) | 520-680 | 500-650 | 500-650 |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 | 200-250 |

| ReH- Mphamvu zochepa zokolola (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Mphamvu yamphamvu (J) kutalika., (+N) | + 20 ° 55 | 0° pa 47 | -10 ° 43 | -20 ° 40 | |

| KV- Mphamvu yamphamvu (J) yodutsa, (+N) | + 20 ° 31 | 0° pa 27 | -10 ° 24 | -20 ° 20 | |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-200 | 200-250 |

| A- Min.elongation Lo = 5,65 √ Ndiye (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Zithunzi za S420NL

| Kunenepa mwadzina (mm): | ku 100 | 100-200 | 200-250 |

| Rm- Mphamvu yamanjenje (MPa) | 520-680 | 500-650 | 500-650 |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 | 200-250 |

| ReH- Mphamvu zochepa zokolola (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Mphamvu yamphamvu (J) kutalika., (+N) | + 20 ° 63 | 0° pa 55 | -10 ° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Mphamvu yamphamvu (J) yodutsa, (+N) | + 20 ° 40 | 0° pa 34 | -10 ° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-200 | 200-250 |

| A- Min.elongation Lo = 5,65 √ Ndiye (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Zithunzi za S460NL

| Kunenepa mwadzina (mm): | ku 100 | 100-200 |

| Rm- Mphamvu yamanjenje (MPa) | 540-720 | 530-710 |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 |

| ReH- Mphamvu zochepa zokolola (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Mphamvu yamphamvu (J) kutalika., (+N) | + 20 ° 63 | 0° pa 55 | -10 ° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Mphamvu yamphamvu (J) yodutsa, (+N) | + 20 ° 40 | 0° pa 34 | -10 ° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Kunenepa mwadzina (mm): | ku 16 | 16-40 | 40-63 | 63-80 | 80-200 |

| A- Min.elongation Lo = 5,65 √ Ndiye (%) | 17 | 17 | 17 | 17 | 17 |

Zowonetsera Zamalonda